Why??

The inspiration for this device comes from me and my friends having to constantly clean our shaker bottles which start to smell if you don’t clean them. Lots of people who work out will take Pre-workout, Post-workout and Protein. Some even take other supplements along with that. Most people use separate bottles so usually three bottles have to be cleaned after every workout which gets extremely tedious and annoying and can take up to 10-20 minutes to fully clean. My idea was to make this process much quicker and easier while allowing some interaction between the user and the device.

The Build

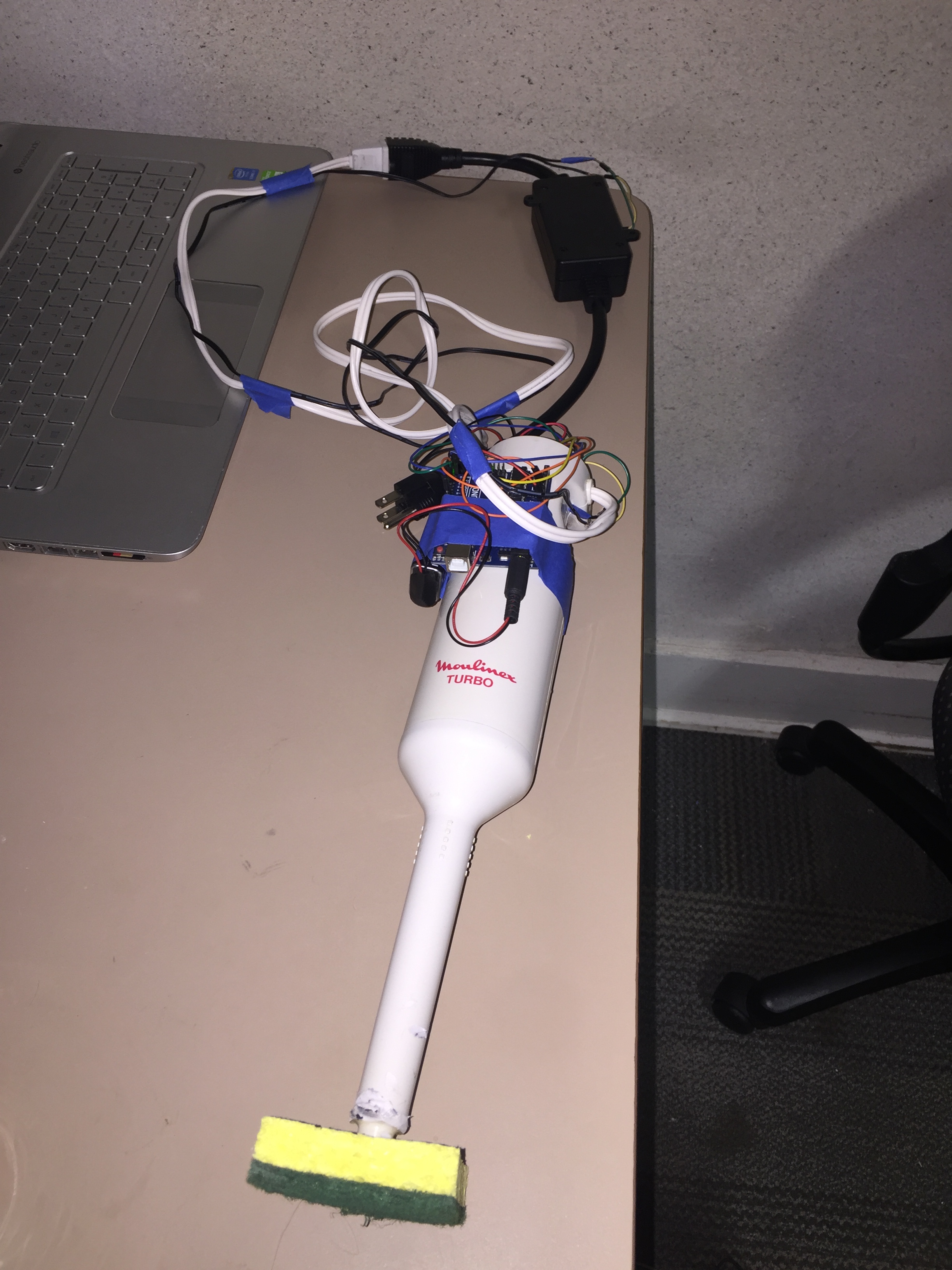

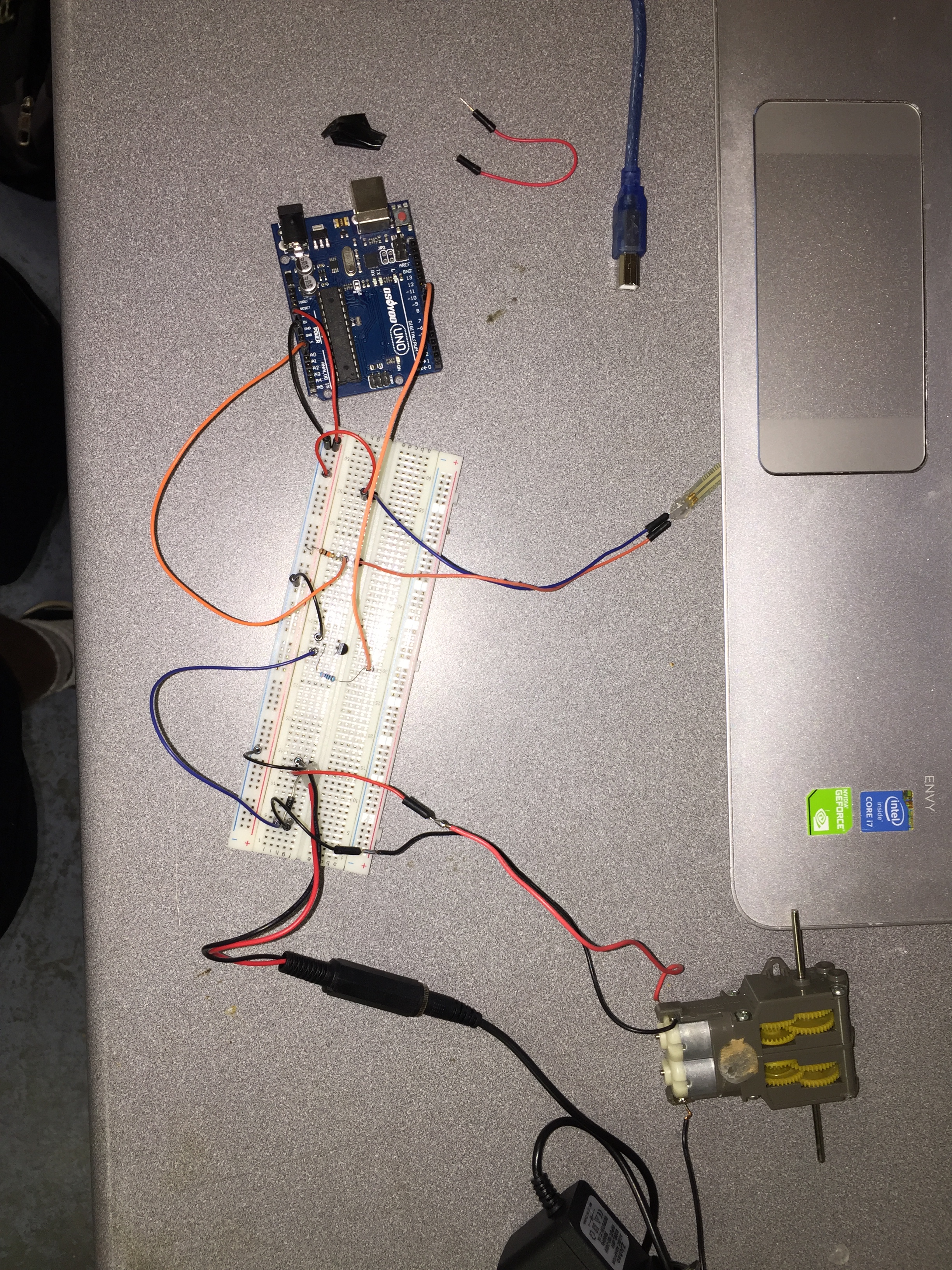

Above is what I started out with; a basic DC motor and a force sensor. I played around with the force sensor code until I had a good idea of how to map the force value to motor speed. Once I was this far I glued a sponge to it and watched it turn, because of the gears there was a decent amount of torque however it turned way too slow for me so I went to goodwill to find an alternative motor and ended up finding the perfect motor and enclosure with it.

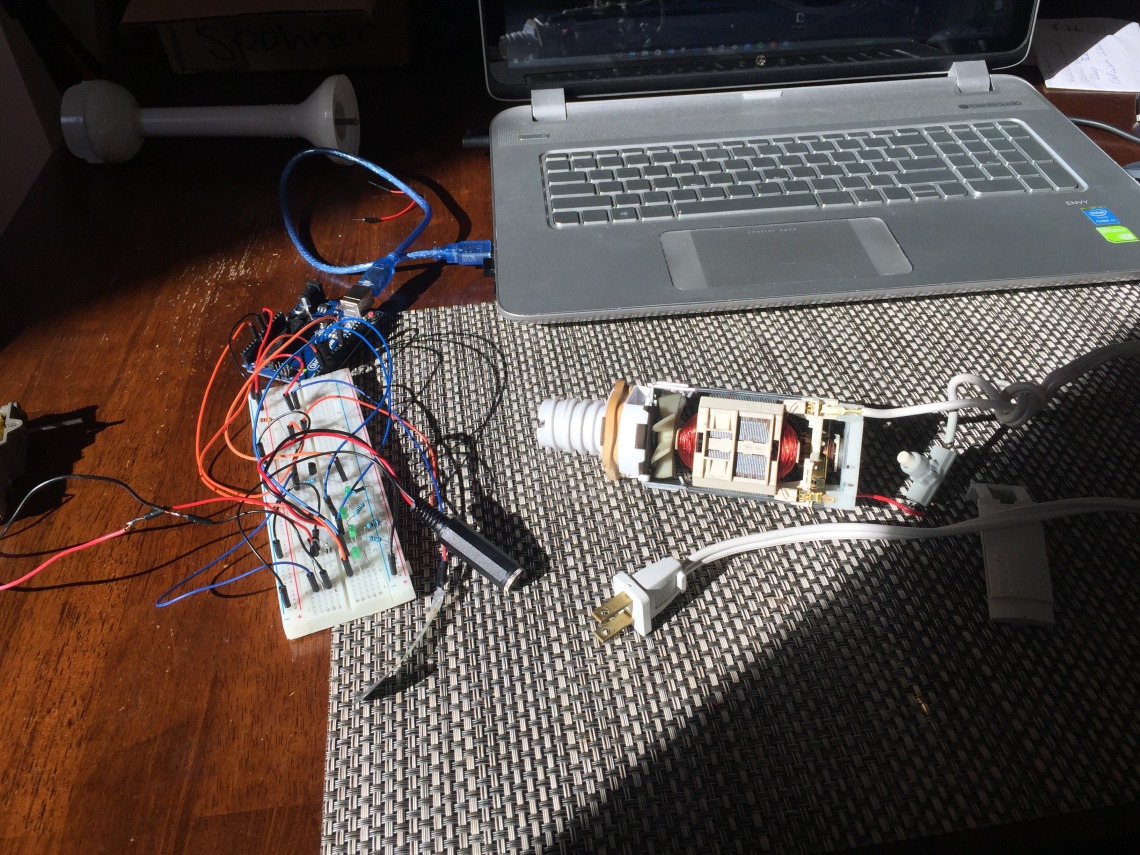

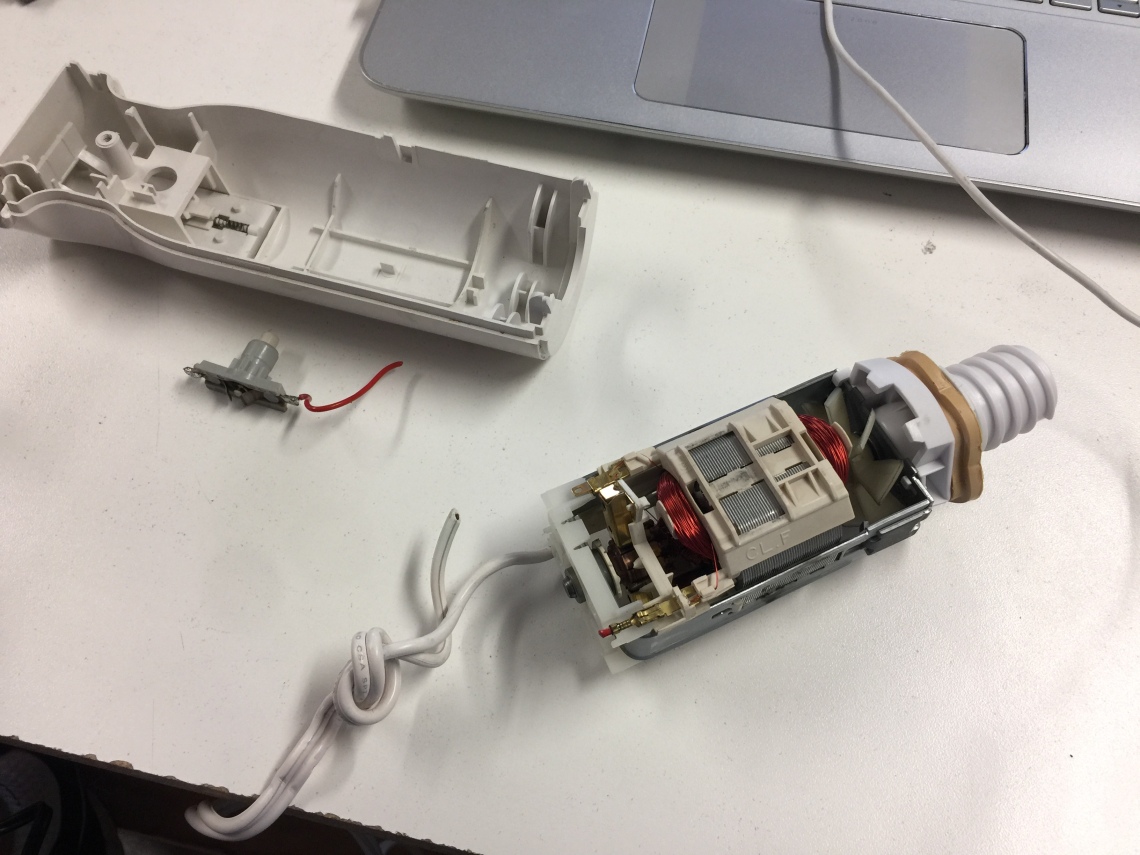

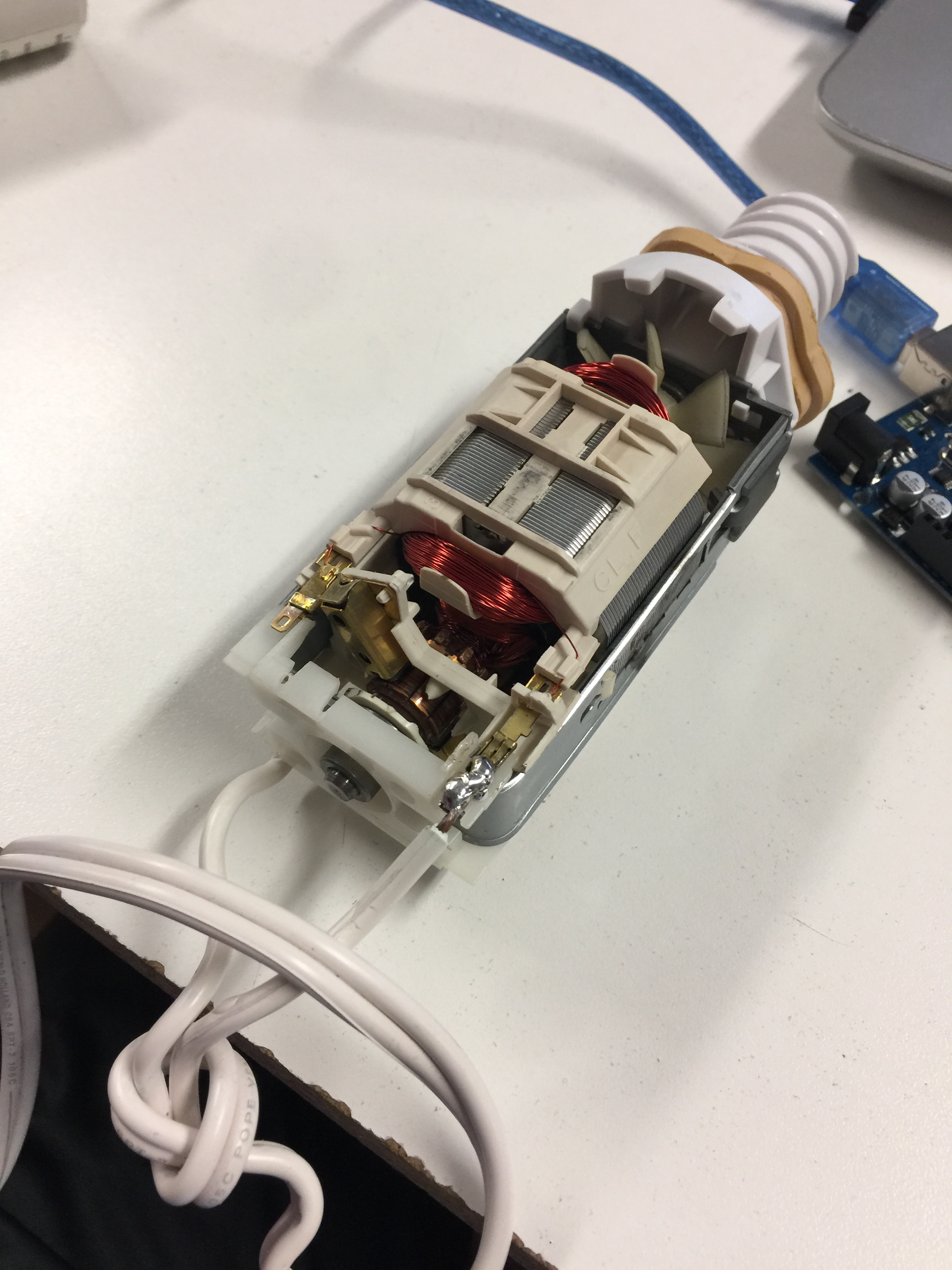

What I got at goodwill for like $1 was a handheld blender with a 120V AC motor that plugged into the wall. Above is the motor taken out of the enclosure and in the background you can see the shaft of the blender which is perfect for cleaning bottles with its long neck. At this point I have also wired up 4 LED’s that would indicate to the user how hard the user was pressing. Four lit up LED’s meant that you were at full power.

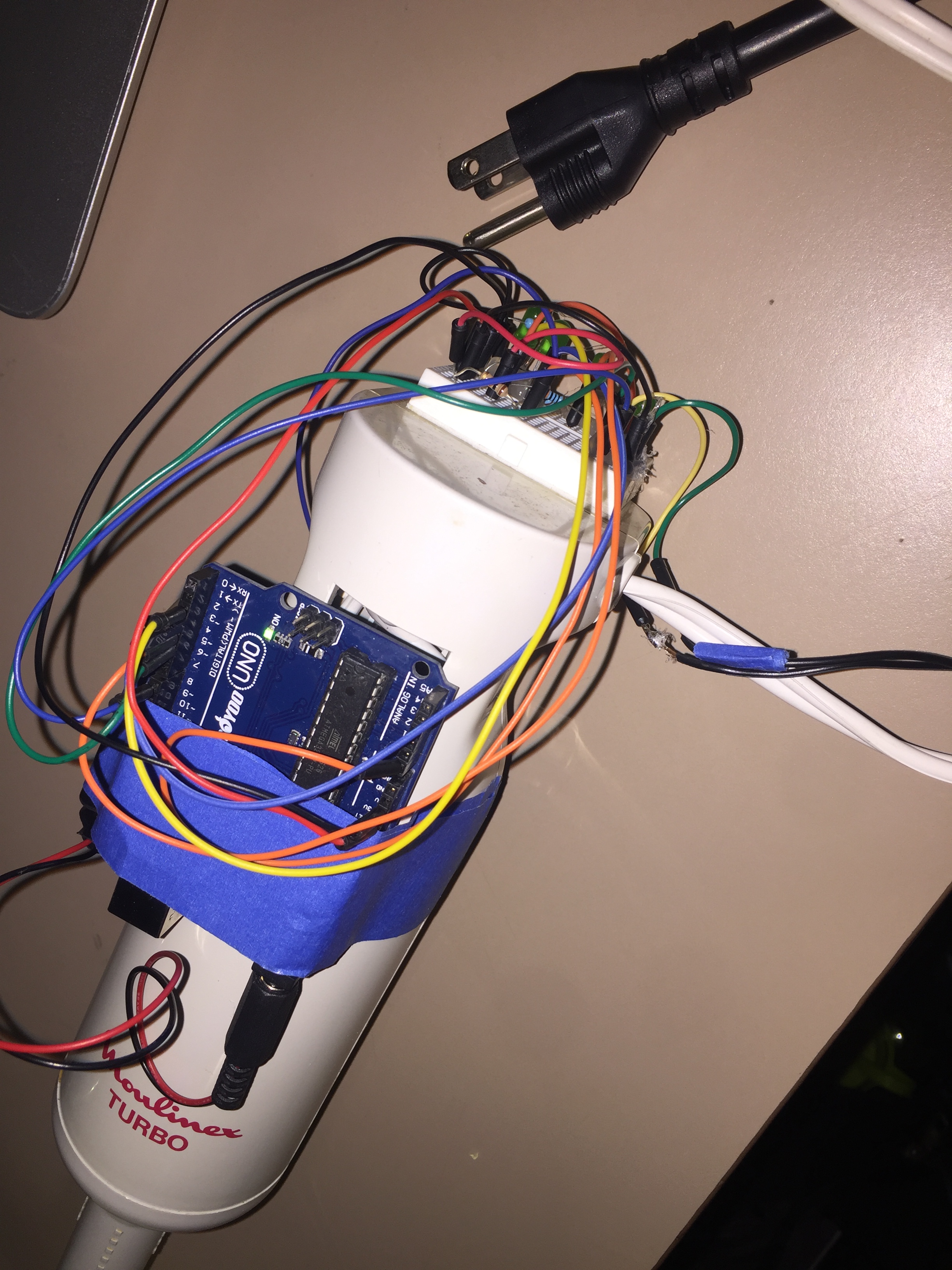

Above are some pictures of the Arduino, a battery (to power the arduino), the LED’s and force sensor mounted to the blender enclosure.

In order to get the blender transformed to a bottle cleaner I had to do some modifications. I cut off the existing button and soldered on the wire directly so that I could use the relay to control the motor entirely. Then I cut off the guard to allow me to attach the sponge and potentially put it into a bottleneck. I also bent the blades at the end of the shaft to make it somewhat less dangerous.

How It Works

Since this motor requires 120 Volts and AC current I had to use a relay to basically turn on/turn off the motor really fast and the variable speed came from the ratio of on time to off time.

if ((forceValue > 2) && currentMotorState == MotorOn) {

digitalWrite(8, HIGH);

if (currentTime - startTime > 20) {

startTime = currentTime;

currentMotorState = MotorOff;

}

}

else if (currentMotorState == MotorOff) {

digitalWrite(8, LOW);

if (currentTime - startTime > pause) {

startTime = currentTime;

currentMotorState = MotorOn;

}

}

Above is the heart of the code and what really makes this thing work. Basically force value is how hard you are pressing and the values would range from 0 – 1010 ish. I have a state machine with an on state and an off state. The motor would initially be in the on state but would only close the relay switch when you applied some force to the sensor (more than 2, if you didn’t touch it, zero was read). All I needed to control the relay was a digital write that sent the signal. This signal would be sent for 20 ms to the motor would always have power for 20 ms and then turn off because the state would go to off after that time. Then, the amount of time (pause) the motor was off depended on how hard you were pressing, little pressure meant long pauses while more pressure was smaller pauses.

Reflection

I am super proud of my creation and am really glad I got to use a motor that actually has some power. I thought it was super cool that I was able to safely control a large voltage along with AC current. It was kind of an awkward way to use the relay but after looking at the data sheet I realized that what I was doing shouldn’t damage the relay since it was rated for 10 ms. I definitely thought that the sponge would fly off if I went full power during my presentation but somehow the hot glue held on. It actually works and can clean surfaces! We had some fake snow (still from December) that it cleaned right off of the wood, the sponge did fly off at the end but it held on pretty well!